DISCOVER SURFOX WELD CLEANING

The SURFOX™ electrochemical weld cleaning system is the most effective method for removing heat tint from welded stainless steel (TIG, Spot, Stick, and MIG), without altering the surface of the parent material.

Fieldwork Units

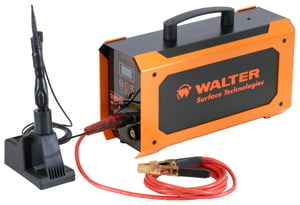

SURFOX MAX

- 2550 Watts of maximum cleaning output

- Includes dual-user capabilities so two users can work with the same machine

- LCD panel with multi-language settings and more precise settings

- Dip & work weld cleaning

- Marking and etching

- Lightweight and portable

SURFOX MINI

- 900 Watts of maximum cleaning output

- Comes with the SURFOX™ cartridge wand

- Can be used with the SURFOX™ dip & work wand kit

- Marking and etching

- Weighs only 16 lbs

SURFOX TURBO

- Powerful and compact

- Dip & work weld cleaning

- Simple to use

- Weld cleaning unit only

- Lightweight and portable

Heavy-duty/Industrial Use

SURFOX 206

- Multi-Language LCD

- Mini Wand & Marking Port

- 4m Wand & Dynamic Flow Pump

- Fume Dispersions System (Air supply needed)

- New 50 AMP Inverter at 3-30V & CPO: 1500W Max

SURFOX 306

- Multi-Language LCD panel

- Mini Wand & Marking Port

- New 6m Wand & Dynamic Flow Pump

- Dual User Dip & Work Port

- Fume Dispersions System (Air supply needed)

- New 85 AMP Inverter at 3-30V & CPO: 2550W Max